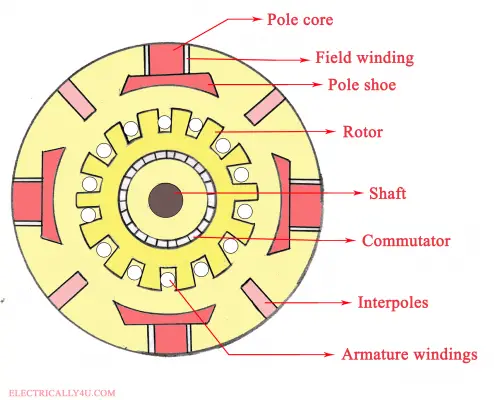

Construction of DC Generator

The construction of DC generator is same as that of the DC motor. It means, a DC machine can be used both as a generator and as a motor.

When the machine is driven by a prime mover, it converts mechanical energy into electrical energy and it is called DC generator.

If an electrical supply is given as the input for DC machine, it gets converted into mechanical output and it is called as a DC motor.

The DC machine consists of two parts: One part is rotating, called rotor and the other part is stationary, called stator.

The major components of a DC machine are:

- Magnetic frame or yoke

- Pole core and pole shoe

- Field coil or winding

- Armature core and winding

- Commutator

- Brushes

- Bearings and shaft

Magnetic Frame or yoke

It is the stationary part of the machine in the shape of hollow cylinder. Poles are fixed at the inner periphery of the yoke.

It acts as the outer cover or frame for the entire machine and serves two main purposes: It is used to carry the magnetic flux produced by the poles. It acts as mechanical support for the machine.

Yoke is usually made of cast iron for small machine, because of its cheapness. But for large machines, it is made of cast steel or rolled steel, due to its high permeability.

The lifting eye, feet and the terminal box are welded to the frame afterwards.

Pole core and pole shoe

The field pole consists of pole cores, pole shoes and field winding. The poles are made of thin laminated sheets, to avoid heating and eddy current loss.

Pole cores are the projecting rectangular parts, which produce magnetic flux needed for the generator, when it is excited by the field winding. It is fitted to the yoke or frame by means of bolts and nuts or rivets.

The pole shoes are located at the end of pole core. The purpose of providing pole shoe in the poles is to make the magnetic field uniform on the surface of the armature.

Following are the main function of the poles

- it acts as a mechanical support to the field coil.

- they reduce the reluctance of the magnetic path.

- they guide and spread out the flux in the air gap.

Field coil or winding

Field coil is made up of copper. They are mounted on the pole core and carry the dc current. The field coils are connected in such a way that adjacent poles have opposite polarity.

When the coils carry dc current, the pole core become an electromagnet and produces the magnetic flux. The magnetic flux passes through the pole core, the air gap, the armature and the yoke.

The number of poles in a DC Generator depends on the speed of the machine and the output for which the machine is designed.

There are several field constructions are adopted according to the type of excitation. In shunt field, more number of turns with small cross sectional are used, in series field only a few turns of large cross sectional area are used and in compound field, both shunt and series field winding are used.

Armature core and winding

In the construction of DC generator, armature core is designed as the rotating part and is built in cylindrical or drum shape with slots on its outer periphery. The purpose of armature is to house the winding and to rotate the conductors in the uniform magnetic field. It is mounted on the shaft.

It is build up of steel lamination which are insulated by each other by thin paper or thin coating of varnish as insulation. The thickness of each lamination is about 0.5 mm. These lamination will reduce the eddy current loss. If silicon sheet is used for armature core, the hysteresis loss will also reduce.

Due to losses, heat will be developed in the armature. To dissipate this heat, a fan is provided at one end of armature. Ventilating ducts (air holes) are also provided in the armature for the purpose of cooling. The width of the ventilating ducts varies from 5 to 10 mm.

The armature winding or coil is placed on slots available on the armature’s outer periphery. The ends of the coils are joined with commutator segments. Insulated higher conductivity copper wire is used for making the coils. There are two types of winding.

- lap winding – Lap winding is used for high current, low voltage generators.

- Wave winding – Wave winding is used for high voltage, low current generators.

Commutator

The commutator provides the electrical connection between the rotating armature coil and the stationary external circuit. It is essentially a cylindrical structure and is built up of wedge shaped copper segments insulated from each other by mica sheets and mounted on the shaft of the machine.

The commutator is a mechanical rectifier which converts the alternating emf generator in the armature winding into direct voltage across the brushes. The ends of the armature coil or winding are connected to commutator segments.

Great care is to be taken while building the commutator because even slight eccentricity will cause the brushes to bounce, which can cause high sparking.

Brushes

The function of brush is to collect the current from the commutator and supply it to the external load circuit. The brushes are manufactured in a variety of compositions to suit the commutation requirements. It is made of carbon, graphite metal graphite or copper and is rectangular in shape.

The brushes are placed in the brush holders which is mounted on rocker arm. The brushes are arranged in rocker arm in such a way that, it touches the commutator.

Brush pressure is adjusted by means of adjustable springs. If the bush pressure is high, the friction produces heating of the commutator and the brushes. If the pressure is too weak, the imperfect contact with the commutator may produce spark.

Bearings and Shaft

For construction of smaller DC generator, ball bearings are used at both the ends of the shaft but for larger machines, roller bearings are used at the driving end and ball bearings are used at the non driving end of the machine.

The shaft is made up of mild steel having maximum breaking strength. It is used to transfer the mechanical power from or to the machine. All the rotating parts including the armature core, commutator, cooling parts and mounted and keyed to the shaft.

Guy good explanation